Research and development of machine tools

Research and development of machine tools, new technologies - design department.

DESIGN DEPARTMENT OF MACHINE TOOLS.

For many years, the Company's Design Department has been preparing projects for modernization and general overhauls of horizontal machine tools, lathes, carousels, rotary tables, etc.. In response to increasing customer requirements, it is expanding its activities to the development and design of brand new machines and equipment.

USE A NEW HEADSTOCK

Use of a new spindle with a spindle diameter of up to 180 mm with a maximum speed up to 3000 rpm and the possibility of cooling through the spindle center.

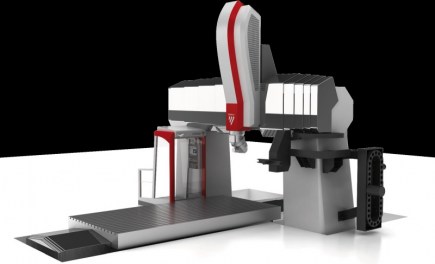

DEVELOPMENT AND CONSTRUCTION OF THE NEW PORTAL MACHINE

distance between columns 3370 mm

travel of the ram 1550 mm

travel Y 3910 mm

travel X 5970 mm - 10,000 mm

DEVELOPMENT AND DESIGN OF A NEW CAROUSEL TABLE FOR MACHINE TOOLS

The main function of this table is to rotate the clamped workpiece in vertical turning mode and precise positioning of the B-line usable, for example, during milling or drilling. Thanks to its versatility, it is possible to use this table for various types of machine tools, especially for portal and horizontal milling machines. The carousel table is equipped with a rotating clamping plate with a diameter of 1,800 mm. The measuring position B is controlled by an angular sensor, which is assembled to a fixed pin in the middle of the table.

VAV (RESEARCH AND DEVELOPMENT) PROJECT OF SPECIAL MACHINE TOOLS: TABLE MILLING MACHINE, PORTAL MILLING MACHINE, CAROUSEL TABLES

The aim of the project implemented in effective cooperation is research and development of new machinery, technologies and materials through the implementation of our own industrial research and experimental development.

EUROPEAN UNION

European Regional Development Fund

OP Entrepreneurship and Innovation for Competitiveness

VAV (RESEARCH AND DEVELOPMENT) PROJECT OF SPECIAL HORIZONTAL BORING MACHINE WITH INTEGRATED FACING HEAD

Project is financially supported by European Union.

The target of project is to develop, test and prepare for serial production a prototype of CNC horizontal boring machine with spindle diameter 100 mm with integrated facing head (HBM 10 FP), that will be after finishing of this project introduced and brought to the market.

EUROPEAN UNION

European Regional Development Fund

OP Entrepreneurship and Innovation for Competitiveness

FERMAT CZ